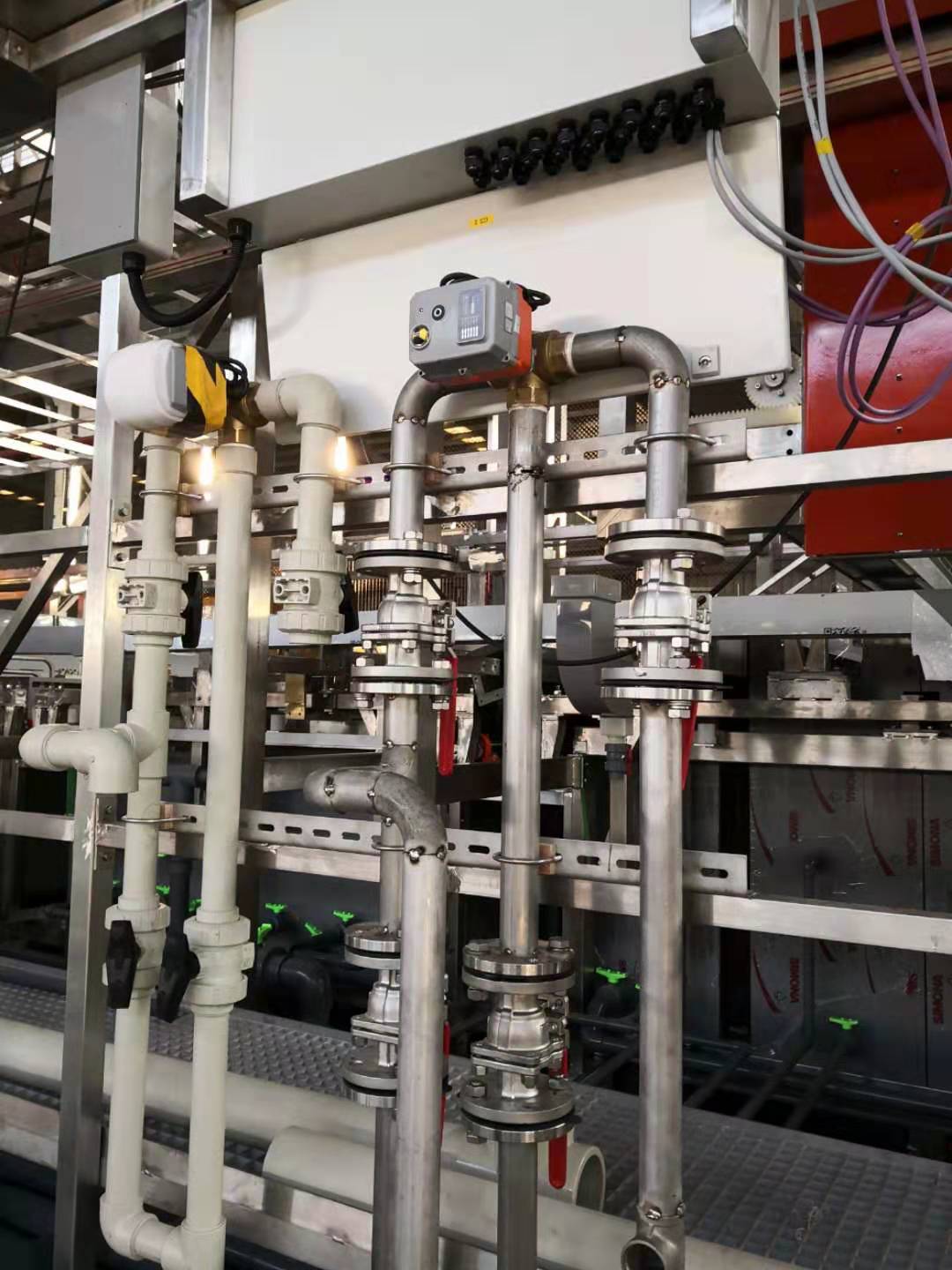

Electroplating equipment

- Customer Success

- Related Products

- Related industry Applications

1. Electric Valves Applications

Precise Chemical Injection: Electric valves control the precise flow and pressure of chemical agents, ensuring that chemicals are introduced into the plating bath at the required rate and speed. This high-precision control minimizes chemical waste and ensures uniformity and consistency of the coating.

Automated Process Control: Electric valves integrate with automation control systems to provide real-time adjustments to the electroplating process. They automatically open and close according to process requirements, reducing manual intervention and improving operational efficiency and process stability.

2. Pneumatic Valves Applications

Chemical Recirculation and Distribution: Pneumatic valves manage the circulation and distribution of chemicals within the plating bath. They offer rapid opening and closing capabilities, adjusting chemical flow rates to ensure even distribution within the bath, enhancing plating effectiveness and product quality.

Stable Operation in High-Pressure Environments: Pneumatic valves excel in high-pressure conditions, handling the pressures encountered during electroplating operations, and ensuring stable system performance.

3. Control Valves Applications

Flow and Pressure Regulation: Control valves are used to finely adjust the flow and pressure of liquids in the electroplating process. They enable precise tuning to maintain stable plating conditions, ensuring uniform coating and high-quality plating results.

Cross-Membrane Pressure Control: In electroplating, control valves accurately regulate the cross-membrane pressure to prevent pressure fluctuations from affecting the plating results, ensuring consistent liquid flow within the plating bath.

Summary

YNTO’s electric valves, pneumatic valves, and control valves significantly enhance the efficiency and quality of the electroplating process. Electric valves optimize chemical injection and automated control, pneumatic valves improve chemical circulation and distribution, and control valves ensure precise flow and pressure regulation. Together, these valves provide robust technical support for efficient operation and high-quality production in electroplating equipment.